Press Capacity:

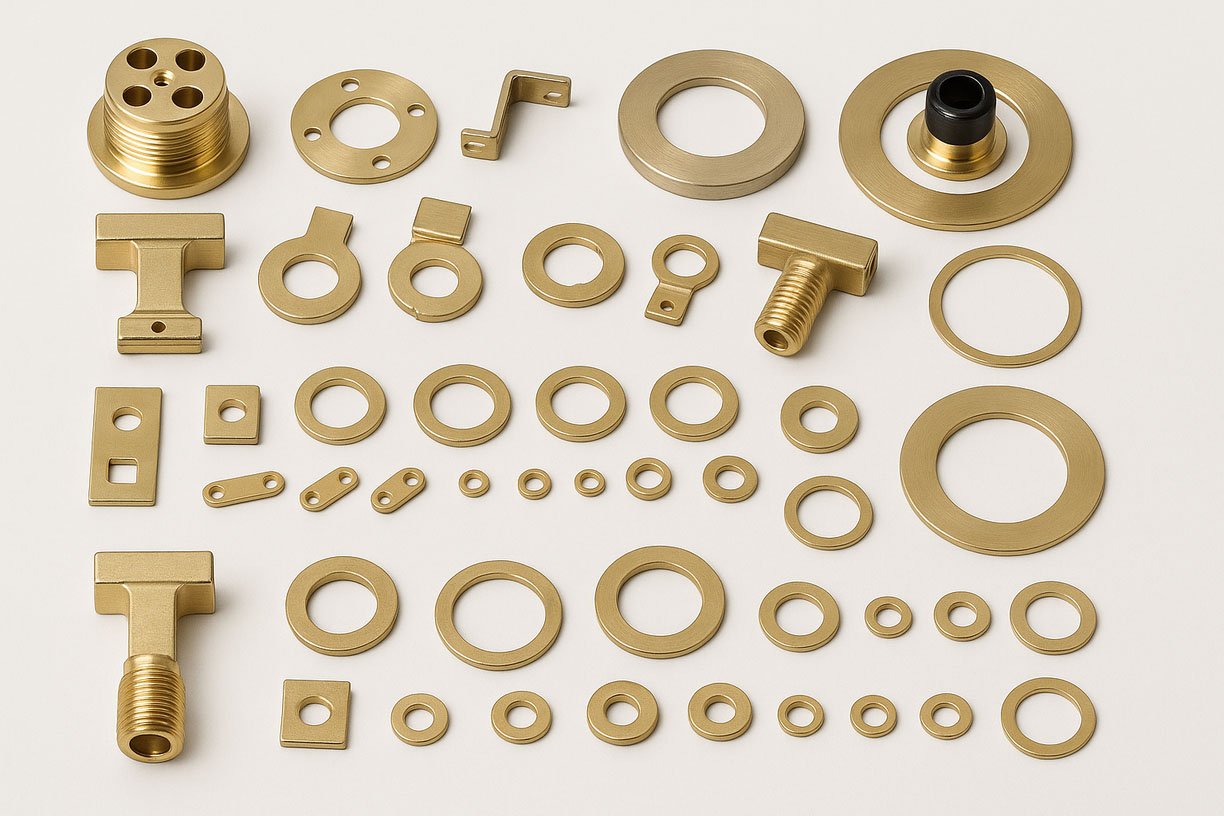

Brass Copper Pressings

Brass Copper Pressings

Professional Press Work, Pressed Parts & Deep Drawn Components Manufacturing

Engineered for demanding pressing applications, our comprehensive Brass Copper Pressings deliver exceptional performance through advanced manufacturing capabilities including brass pressed parts and copper pressed components for diverse industrial applications, press work and pressing operations using 400 tone press capacity, deep drawn components and special pressings for electromechanical applications, washers manufactured to BS 4320:1968, DIN 125, 433, and 9021 standards, specialized pressings for switchgear, transformer, elevator, heater, and electromechanical equipment, pressing capabilities up to 5mm thickness for heavy-duty applications, and comprehensive material options including brass, copper, and stainless steel with complete pressing solutions. Our comprehensive pressing range includes brass pressed parts for electrical applications, copper pressed components for thermal management, stainless steel pressings for corrosion resistance, deep drawn components for complex geometries, special pressings for custom requirements, and washers for standard applications. Available with BS 4320:1968, DIN 125, 433, and 9021 standard compliance, 400 tone press capacity for heavy-duty operations, up to 5mm thickness capability for robust applications, and specialized electromechanical application focus, these pressings provide optimal performance and reliable pressed component solutions for long-term reliability in demanding applications requiring superior pressing quality, exceptional dimensional accuracy, and professional manufacturing capabilities with comprehensive material choices and thickness options that deliver competitive solutions for challenging industrial, electrical, and electromechanical pressing applications.

Key Specifications

-

-

Thickness Range:

Up to 5mm

-

Standards:

BS 4320, DIN 125/433/9021

Comprehensive Pressing Types

Brass Pressed Parts

Electrical ApplicationsProfessional brass pressed parts designed for electrical applications providing superior conductivity and reliable performance in electromechanical systems.

- Superior conductivity

- Electrical applications

- Reliable performance

Copper Pressed Components

Thermal ManagementHigh-quality copper pressed components designed for thermal management applications with excellent heat transfer properties and corrosion resistance.

- Excellent heat transfer

- Corrosion resistance

- Thermal management

Deep Drawn Components

Complex GeometriesAdvanced deep drawn components for complex geometries providing specialized solutions for demanding applications requiring intricate shapes and forms.

- Complex geometries

- Specialized solutions

- Intricate shapes

Stainless Steel Pressings

Corrosion ResistanceProfessional stainless steel pressings providing superior corrosion resistance and mechanical strength for demanding environmental conditions.

- Superior corrosion resistance

- Mechanical strength

- Environmental resistance

International Washer Standards

BS 4320:1968 Standard

Plain washers manufactured to BS 4320:1968 British Standard providing reliable fastening solutions with dimensional accuracy and quality assurance.

- British Standard compliance

- Dimensional accuracy

- Quality assurance

DIN 125, 433 & 9021 Standards

Comprehensive DIN standard washers including DIN 125, 433, and 9021 specifications providing German engineering quality and international compatibility.

- German engineering quality

- International compatibility

- Multiple DIN specifications

Specialized Electromechanical Applications

Switchgear & Transformer Components

Power SystemsSpecialized pressings for switchgear and transformer applications providing reliable electrical connections and superior performance in power systems.

- Electrical connections

- Power systems

- Superior performance

Elevator & Heater Components

Mechanical SystemsCustom pressings for elevator and heater applications providing mechanical reliability and thermal performance in demanding operating conditions.

- Mechanical reliability

- Thermal performance

- Operating conditions

Advanced Press Capabilities

400 Tone Press Capacity

High-capacity 400 tone press providing exceptional force for heavy-duty pressing operations and complex component manufacturing.

- Exceptional force

- Heavy-duty operations

- Complex manufacturing

Up to 5mm Thickness

Comprehensive thickness capability up to 5mm accommodating diverse material requirements and robust component specifications.

- Diverse material requirements

- Robust specifications

- Thickness capability

Special Pressing Operations

Specialized pressing operations for custom requirements including deep drawing, forming, and complex geometry production capabilities.

- Custom requirements

- Deep drawing

- Complex geometry

Quality Assurance & Manufacturing Excellence

Dimensional Accuracy

Precision manufacturing ensures dimensional accuracy and consistent quality across all pressed components and washers meeting international standards.

- Precision manufacturing

- Dimensional accuracy

- Consistent quality

International Standards Compliance

Complete compliance with BS 4320:1968, DIN 125, 433, and 9021 standards ensuring quality assurance and international compatibility.

- International standards

- Quality assurance

- Global compatibility

Typical Applications

Electrical & Power Systems

Essential for electrical and power systems including switchgear components, transformer parts, electrical connections, power distribution equipment, and electromechanical assemblies requiring reliable performance.

- Switchgear components

- Transformer parts

- Electrical connections

- Power distribution

Mechanical & Industrial Systems

Critical for mechanical and industrial systems including elevator components, heater elements, industrial machinery, mechanical assemblies, and specialized equipment requiring precision pressings.

- Elevator components

- Heater elements

- Industrial machinery

- Mechanical assemblies

Performance Benefits

Advanced Press Capabilities

400 tone press capacity with up to 5mm thickness capability providing exceptional force for heavy-duty pressing operations and complex component manufacturing.

International Standards Compliance

Complete compliance with BS 4320:1968, DIN 125, 433, and 9021 standards ensuring quality assurance and global compatibility.

Comprehensive Material Options

Brass, copper, and stainless steel material choices providing optimal properties for electrical, thermal, and corrosion resistance applications.

Professional Pressing & Deep Drawing Solutions

Our comprehensive brass copper pressings serve critical applications across electrical and power systems, mechanical and industrial systems, switchgear components, transformer parts, electrical connections, power distribution equipment, electromechanical assemblies, elevator components, heater elements, industrial machinery, mechanical assemblies, and specialized equipment requirements. These pressings are essential for reliable component solutions where superior pressing quality, exceptional dimensional accuracy, and professional manufacturing capabilities are required in demanding applications where pressing design provides exceptional performance and reliable solutions with advanced press technology that delivers superior strength and long-term reliability in challenging electrical, mechanical, and industrial pressing applications.

Key Benefits

- 400 tone press capacity with up to 5mm thickness capability

- International standards compliance including BS 4320:1968 and DIN specifications

- Comprehensive material options including brass, copper, and stainless steel

- Specialized electromechanical applications for switchgear, transformer, elevator, and heater

- Deep drawn components and special pressings for complex geometries

- Precision manufacturing with dimensional accuracy and quality assurance

Request a Schedule For

Free Consultation